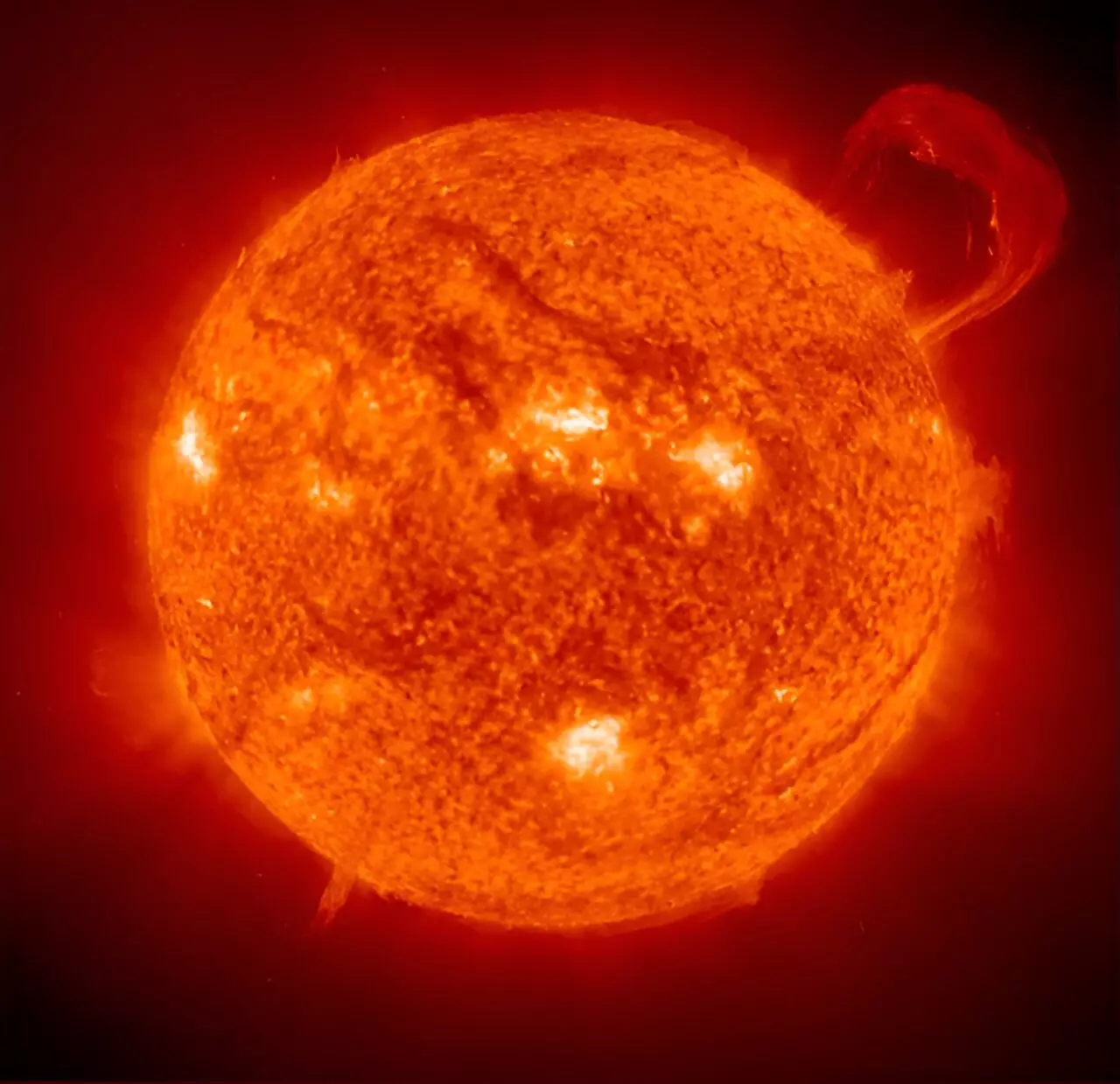

Nuclear fusion, the same process that powers the stars, has long been proposed as a potential power source for humanity. Unlike current nuclear fission plants, fusion can provide clean and renewable energy without the radioactive waste. By slamming together isotopes of hydrogen in an ultra-hot gas or “plasma” contained by a powerful magnetic field, fusion facilities can produce helium, harvesting the difference in mass as energy. However, one crucial aspect that scientists need to determine is the ideal mix of hydrogen isotopes for fusion plasma performance. In a recent study published in The European Physical Journal D, Associate Professor Mohammed Koubiti explores the potential of using machine learning combined with spectroscopy to predict the content of tritium in fusion plasmas.

Replacing Spectroscopy with Machine Learning

Traditional spectroscopy methods are time-consuming and require extensive analysis. With the aim of reducing reliance on spectroscopy, Koubiti proposes combining it with deep learning algorithms to predict the tritium content in fusion plasmas more efficiently. By using machine learning, he hopes to optimize fusion power plants’ performance and ensure the strict management and control of tritium content, according to the limits imposed by regulatory authorities.

While acknowledging that spectroscopy still plays a crucial role in his research, Koubiti believes that deep learning techniques have the potential to enhance tritium content prediction in fusion plasmas. He utilizes spectroscopy to identify additional features that can be utilized by deep learning algorithms, ultimately aiming to predict tritium content in real-time. By developing this approach, he aims to reduce the time-consuming nature of spectroscopy analysis and enhance the overall efficiency of fusion power plants.

Expanding Beyond Spectroscopy

Koubiti’s research project is not limited to plasma spectroscopy alone. He envisions extending the use of deep learning techniques to various magnetic fusion devices such as tokamaks (such as JET, ASDEX-Upgrade, or WEST), DIII-D, and stellarators. Stellarators, unlike tokamaks, rely on external magnets to confine plasma. By identifying the non-spectroscopic features that are essential for any deep learning algorithm, Koubiti aims to broaden the application of machine learning techniques in the field of fusion plasma research.

In the pursuit of fusion energy as a sustainable and abundant power source, scientists must continually strive for improved plasma performance. By leveraging machine learning algorithms, Koubiti’s research aims to revolutionize the prediction of tritium content in fusion plasmas. Real-time monitoring of tritium levels can optimize the performance of nuclear power plants, ensuring a controlled and managed fusion process. This development could lead to unprecedented advancements in the field and unlock the full potential of nuclear fusion as a viable energy source.

The integration of machine learning and spectroscopy holds significant promise for advancing fusion plasma research. Koubiti’s groundbreaking study represents a crucial step towards optimizing plasma performance through the power of deep learning algorithms. As the demand for clean and renewable energy intensifies, the successful implementation of machine learning techniques in fusion power plants could revolutionize the way we harness energy. With further research and experimentation on various fusion devices, the potential to extend machine learning techniques beyond plasma spectroscopy opens up new possibilities for the future of nuclear fusion. The world may be one step closer to unlocking the incredible power of the stars right here on Earth.

Leave a Reply